The UAE’s dry docks industry is one of the world’s most advanced centers for shipbuilding, repair, and maritime engineering. From Dubai to Abu Dhabi, shipyards handle massive vessels and complex projects that demand exceptional precision, safety, and efficiency. Yet, these same environments remain among the most hazardous, with workers constantly exposed to confined spaces, heavy lifting, scaffolding, welding, and elevated work zones.

For decision-makers and safety leaders, traditional classroom sessions and toolbox talks are no longer enough. As compliance standards evolve and global clients demand greater accountability, Virtual Reality (VR) Safety Training has emerged as a smarter, safer, and more effective approach to workforce readiness.

Why Safety Training is Mission-Critical in Dry Docks Industry

Every shipyard operation involves potential danger, but with the right safety systems, most risks can be mitigated before they turn into incidents.

In dry docks, workers often enter confined areas such as tanks, hulls, and ballast chambers, facing threats like suffocation, toxic gases, or limited escape options. Maintenance and assembly tasks require working at significant heights on scaffolding or crane platforms, where any mistake can lead to severe injuries.

Adding to this complexity are heavy equipment operations such as EOT cranes, forklifts, and boom lifts, where mishandling can cause major collisions or mechanical failures. Finally, fire and welding hazards remain constant, as sparks and flammable residues can trigger onboard fires or explosions.

Each of these risks has operational consequences — from project delays and financial losses to damage in reputation. This makes safety training not just a compliance requirement but a business-critical investment.

Explore Our Case Studies

How VR Safety Training Transforms Shipyard Readiness

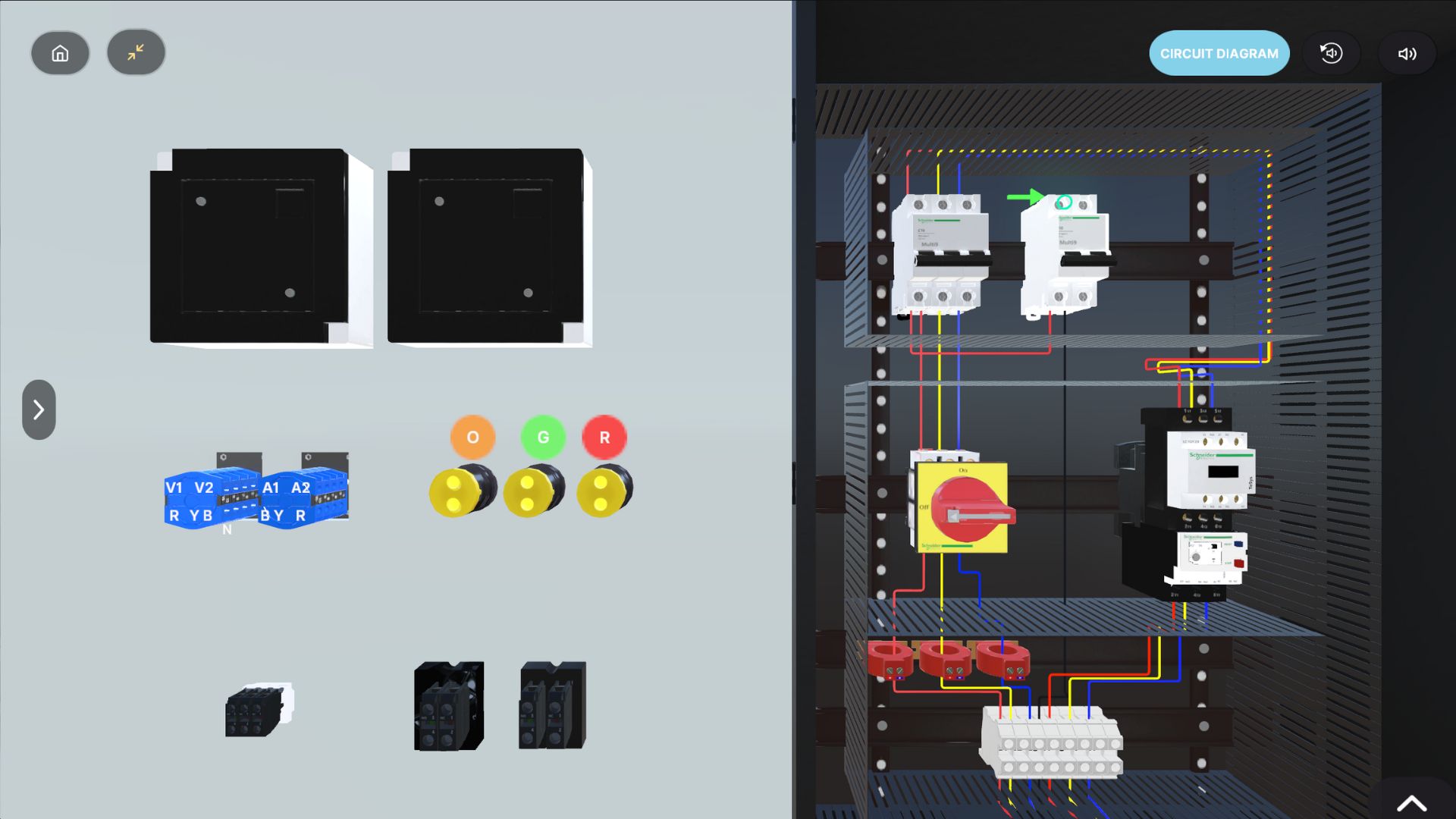

Virtual Reality (VR) creates a life-like, immersive environment where workers can safely practice hazardous operations before they step onto a real deck or dry dock floor. This method shifts learning from theory to experience — helping workers build reflexes, decision-making skills, and procedural accuracy in a controlled setting.

For shipyard managers and HSE heads, VR safety programs offer several clear advantages:

- Regulatory Alignment: Every module is designed to meet UAE Maritime, MOHRE, and port authority safety standards.

- Risk-Free Simulation: Trainees can practice confined space entries, scaffolding inspections, and crane operations without exposure to real danger.

- Performance Analytics: Managers receive measurable insights on how workers follow safety procedures, helping identify training gaps and issue certifications.

- Multilingual Deployment: With multinational workforces across UAE docks, VR modules can be deployed in multiple languages for better understanding and consistency.

- Higher Confidence, Lower Downtime: Workers who train through VR enter the site better prepared, more confident, and significantly less prone to accidents.

By combining realistic simulations with analytics, dry dock companies can not only reduce incidents but also improve productivity and team confidence.

VR Applications in Dry Dock Safety Training

The UAE’s leading shipyards are already integrating VR-based modules into their training programs. Some key applications include:

- Confined Space Entry Training: Simulations cover safe entry procedures, gas detection, ventilation setup, and emergency evacuations.

- Work-at-Height Training: Workers learn proper harness usage, anchor placement, and ladder balance through step-by-step guidance.

- Crane & Equipment Operation: Modules teach safe load lifting, movement coordination, and emergency shutdowns with full control simulation.

- Fire & Hazard Response: Realistic fire spread scenarios train workers to identify gas leaks, handle extinguishers, and execute safe evacuations.

Each module reinforces both technical competence and hazard awareness, allowing teams to make mistakes virtually, learn instantly, and perform safely in reality.

Why UAE Dry Dock Leaders Should Act Now

The UAE continues to strengthen its reputation as a global maritime hub, hosting some of the most sophisticated ship repair and construction facilities. With global clients expecting international-level safety and operational excellence, the adoption of VR safety training is no longer optional, it’s a clear marker of leadership and innovation.

Organizations implementing VR-based safety training are already seeing tangible benefits, including improved compliance scores, reduced lost-time injuries, and stronger worker morale. Beyond compliance, it helps build a culture of safety and innovation, attracting global clients who value advanced operational standards.

Conclusion

For senior leaders in the UAE’s dry docks industry, VR safety training is more than a digital upgrade, it’s a strategic enabler. By immersing workers in realistic maritime environments and tracking their performance in real-time, shipyards can ensure a workforce that is safer, smarter, and fully compliant with UAE regulations.

As the maritime sector continues to expand, embracing VR-driven learning ensures safer workers, stronger operations, and sustainable growth, positioning your organization at the forefront of the UAE’s evolving industrial landscape.

Ready to Lead Safety Standards in Dry Docks?

With immersive VR safety training designed for the dry docks industry, Spatio empowers your teams to operate safely, efficiently, and in full compliance.

Explore Our Case Studies

Related Posts

Nothing found.