About Our Solutions

In metal manufacturing, one lapse can stop a line or injure a worker. Spatio builds VR simulators that let your workforce practice high-risk tasks and daily workflows in a safe, controlled environment before they step on the floor.

Our focus on safety and operations helps operators, riggers, crane drivers, maintenance, and supervisors work with confidence and consistency without disrupting production.

Real-World Scenarios

Train for melting, handling, machining, and packaging situations.

Compliance Assured

Align training with HSE, OSHA, machine guarding, and LOTO requirements.

Improved Retention

Repetition, feedback, and assessments improve on-job performance.

Global Scaling

Roll out consistently across teams, plants, bays, locations and shifts.

Custom Modules For Metal Manufacturing

Comprehensive VR modules for steel, non-ferrous, and fabricated metal operations.

Safety Training Modules

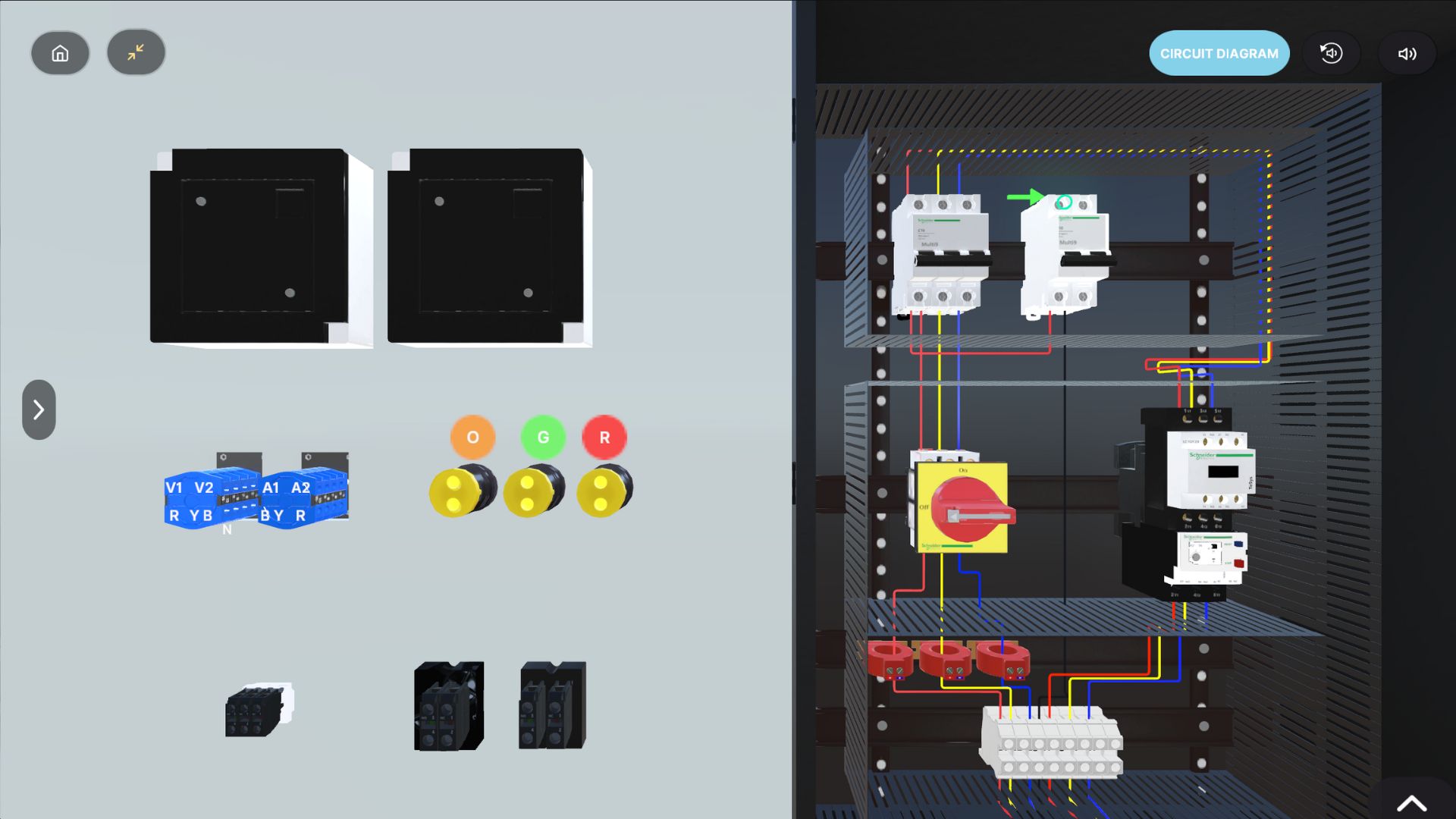

Lockout Tagout and Machine Isolation

Apply LOTO steps, verify zero energy, and restore safely after maintenance on presses, mills, conveyors, and furnaces.

Overhead Crane and RiggingSafety

Inspect slings, choose hitch types, control swing, use taglines, read signals, and coordinate lifts with spotters on busy bays.

Molten Metal Handlingand PPE

Stage ladles, control pour rates, maintain distances, manage splashes, check PPE integrity, and follow emergency procedures.

Exposure & Respiratory Safety

Identify airborne hazards, select respirators, perform fit checks, use ventilation, control dust, and follow cleaning and replacement procedures.

Hot Work and Fire Safety

Manage permits, gas checks, fire watch, extinguisher selection, and post-work clearance around flammables and dust hazards.

Pickling, Plating & Chemical Safety

Read SDS, choose PPE, control splashes, neutralize minor spills, segregate waste, and verify ventilation and bonding.

Operations Training Modules

Furnace Charging and Tapping

Plan charge mix, preheat checks, lance positioning, slag control, tapping sequence, and safe transfer to ladles.

Casting and Mold Management

Prepare molds, control pour temperature, manage gating, prevent defects, and follow shakeout and cooling procedures.

Rolling Mill Basics

Pass schedules, roll gaps, coolant flow, cobble response, line speed control, and safe changeover practices.

Torpedo Operations Training

Train hot metal transport procedures, track movement control, tilt and transfer checks, temperature awareness, spill prevention, and emergency response drills.

MHE Operations Training

Train Operating Material Handling Equipments like EOT and gantry cranes, forklifts, reach trucks, pallet trucks, tow tractors, scissor lifts, and coil handling equipment for safe operations.

Truck Loading Operations Training

Learn load planning, dunnage placement, crane or forklift coordination, strap tensioning, edge protection, weight limits, documentation, and safe dispatch checks.

Heat Treatment and Quenching

Soak times, temperature verification, quench media safety, distortion control, labeling, and traceability during batches.

Finishing, Painting, and Galvanizing

Surface prep, bath checks, cure windows, fume ventilation, and defect prevention for consistent appearance and corrosion performance.

Anode Movement Operations

Practice safe lifting, positioning, and transfer of anodes, maintain clear zones, coordinate signals, prevent collisions, and follow SOP sequencing.

Who We Are

Spatio builds custom VR simulators for high-risk, high-throughput environments. We mirror your layouts, equipment, SOPs, and permits across melt shops, rolling mills, fabrication cells, and finishing lines. Teams train on scenarios that match real work, improving safety, speed, and first-time quality.

60%

Improvement in SOP adherence

43%

Reduction in incidents

75%

Increase in knowledge retention

70%

Reduction in training costs

Contact Us

Case Studies

What Our Clients Say

New operators learned furnace and crane routines without touching hot metal. First-month errors fell, and supervisors coached with clear session playbacks.

Operations Manager

Specialty Chemicals Plant

Frequently Asked Questions

Teams practice real tasks without risk. Repetition builds muscle memory and better decisions under pressure. Clients report fewer incidents and faster onboarding.

Yes. We replicate your bays, cranes, furnaces, presses, interlocks, and paperwork so skills transfer directly to production.

Spatio supports Meta Quest, Pico, and HTC Vive. We guide headset selection, space planning, and device management for multi-site deployments.

Dashboards show completions, scores, errors, and time to competency. Session playbacks support coaching. Data integrates with your LMS and exports for audits.

Yes. Voice and on-screen text can be localized to English, Arabic, Hindi, Urdu, and other languages used across your sites.

Standard modules deploy in two to four weeks. Custom programs that mirror your equipment and SOPs typically take eight to twelve weeks.

Ready to raise safety, throughput, and first-time quality across your plants?

News & Insight

We share the latest breakthroughs, innovations, andupdates in the XR & AI industry