About Our Solutions

In chemical facilities, small mistakes can escalate quickly. Spatio builds VR simulators that let your workforce practice high-risk tasks and daily workflows in a safe, controlled environment before they step into live units.

Our focus on process safety and operations helps operators, technicians, supervisors, and lab staff work with confidence and consistency without disrupting production schedules.

Real-World Scenarios

Train for unit start-ups, transfers, sampling, and emergencies.

Compliance Assured

Align training with HSE, OSHA PSM, NFPA, and permit control.

Improved Retention

Repetition and feedback improve performance.

Global Scaling

Roll out consistently across plants and terminals.

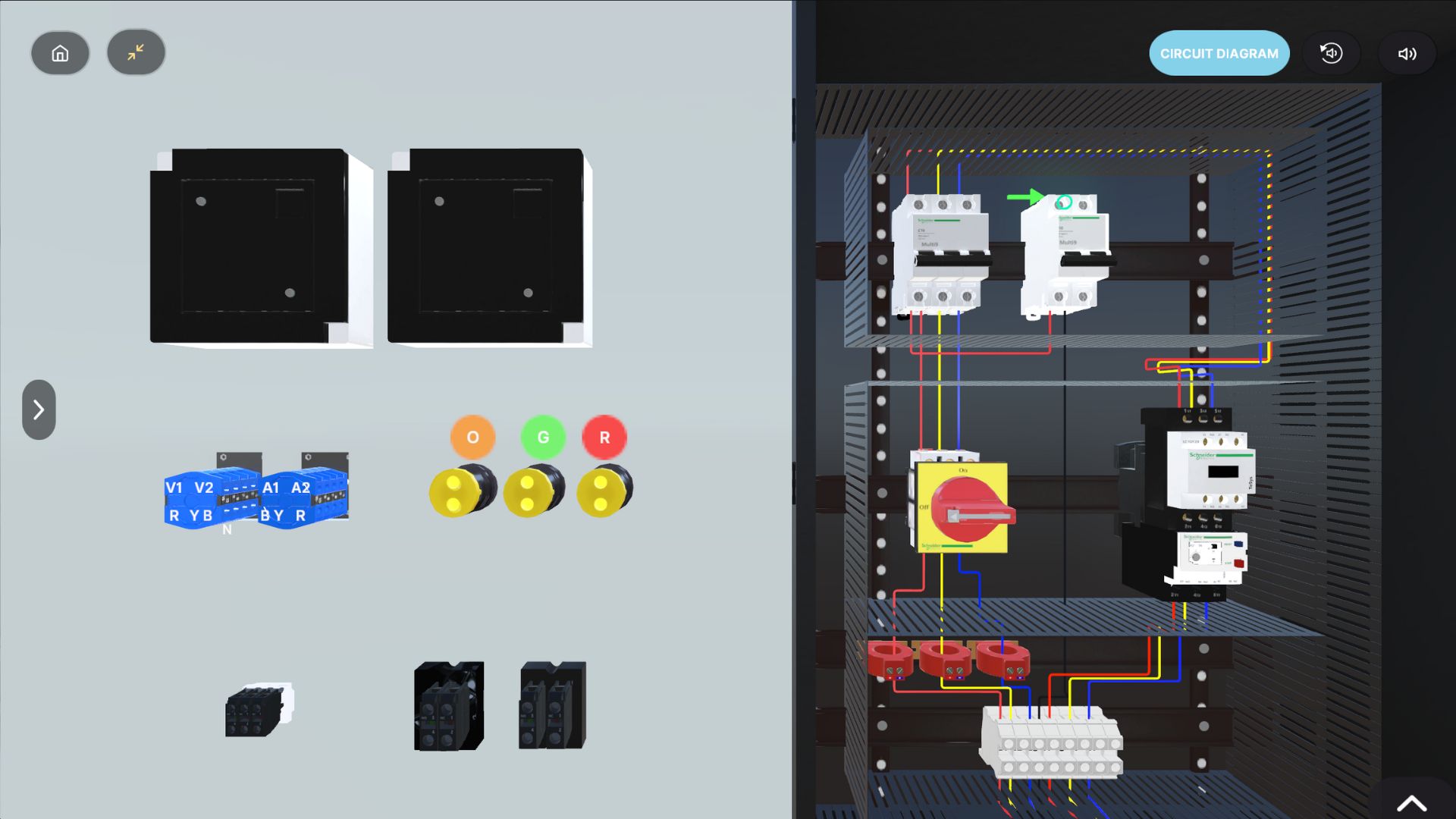

Custom Modules For Chemical Industry

Comprehensive VR modules designed for chemical manufacturing and distribution operations.

Safety Training Modules

Process Safety Fundamentals

Recognize hazards, barriers, and critical controls. Practice permit systems, alarms, and safe operating limits to prevent loss of containment.

PPE and Respiratory Safety

Select correct PPE, don safely, avoid contamination, respond to exposure risks, and follow decontamination steps accurately.

Chemical Storage Safety

Segregate Chemicals, label clearly, control temperatures, ensure ventilation, manage spills and maintain compliant storage records daily.

Hot Work and Cold Work Safety

Manage permits, gas testing, isolation, fire watch, line breaking controls, safe tools, and post-work clearance across hazardous zones.

Hazardous Materials Handling

Read labels and SDS, select PPE, manage small spills, segregate waste, and move containers safely through controlled zones.

Chemical Fire Safety

Identify flammables, control ignition sources, choose correct extinguishers, evacuate safely, and report incidents.

Operations Training Modules

Tanker Loading and Unloading

Verify permits, bond and ground, connect hoses, line up valves, monitor flow and levels, prevent spills, and complete safe disconnection.

Reactors and Mixing Operations

Follow batch sequencing, charge materials safely, control temperature, monitor pressure, respond to deviations, and document critical checks.

Heat Exchanger Operations

Line up valves, verify seals, bond and ground, start pumps, monitor pressures, and complete transfers to specifications.

Material Handling Equipment

Train forklifts, reach trucks, pallet jacks, stackers, order pickers, tow tractors, scissor lifts, conveyors, dock levellers, and ASRS safely.

Decantation Operation Training

Practice settling checks, valve lineup, controlled draining, preventing cross-contamination, handling sludge, and documenting results safely.

Chemical Spill First Response

Assess spill type, raise alarm, isolate area, choose PPE, stop source safely, contain with kits, report, and begin decontamination.

Who We Are

Spatio builds custom VR simulators for high-risk, compliance-critical environments. We mirror your layouts, equipment, SOPs, and permits across production units, terminals, and labs. Teams train on scenarios that match real work, improving safety, speed, and product quality.

60%

Improvement in SOP adherence

43%

Reduction in incidents

75%

Increase in knowledge retention

70%

Reduction in training costs

Contact Us

Case Studies

What Our Clients Say

New operators learned start-ups and transfers without touching a valve. VR lowered first-month errors and strengthened permit discipline across shifts.

Operations Manager

Specialty Chemicals Plant

Frequently Asked Questions

Teams practice real tasks without risk. Repetition builds muscle memory and better decisions under pressure. Clients report fewer incidents and faster onboarding.

Yes. We replicate your equipment, interlocks, layouts, and paperwork so skills transfer directly to live operations.

Spatio supports Meta Quest, Pico, and HTC Vive. We guide headset selection, space planning, and fleet management for multi-site deployments.

Dashboards show completions, scores, errors, and time to competency. Session playbacks support coaching. Data integrates with your LMS and exports for audits.

Yes. Voice and on-screen text can be localized to English, Arabic, Hindi, Urdu, and other languages used across your sites.

Standard modules deploy in two to four weeks. Custom programs that mirror your equipment and SOPs typically take eight to twelve weeks.

Ready to raise safety and throughput across your chemical facilities?

News & Insight

We share the latest breakthroughs, innovations, andupdates in the XR & AI industry