About Our Solutions

In high-throughput facilities, small errors multiply fast. Spatio builds VR simulators that let your workforce practice high-risk tasks and daily workflows in a safe, controlled environment before they step on the floor.

Our focus on safety and operations helps supervisors, operators, pickers, and packers work with confidence and consistency without disrupting live shifts.

Real-World Scenarios

Train for receiving, storage, picking, packing, and dispatch.

Compliance Assured

Align training with HSE, OSHA, fire safety, and MHE standards.

Improved Retention

Repetition and feedback strengthen on-job performance.

Global Scaling

Roll out consistently across DCs, hubs, and cross-dock sites.

Custom Modules For Warehouses

Comprehensive VR modules designed for warehouse operations and safety.

Safety Training Modules

Material Handling Equipment Safety

Perform pre-use checks, maintain stability, protect pedestrians, control speeds, handle loads correctly and park compliantly every shift.

Robotics Co-Working Safety

Understand robot zones, read signals, maintain distances, use e-stops, follow lockout steps, avoid pinch points, and report anomalies promptly.

Manual Handling and Ergonomics

Assess loads, use aids, apply safe lifting, rotate tasks, take microbreaks, and reduce strains and sprains during sustained shifts.

Fire Safety for Warehouses

Recognize alarms, choose extinguishers, control small fires, coordinate evacuation, muster, verify headcounts, and log post-incident actions.

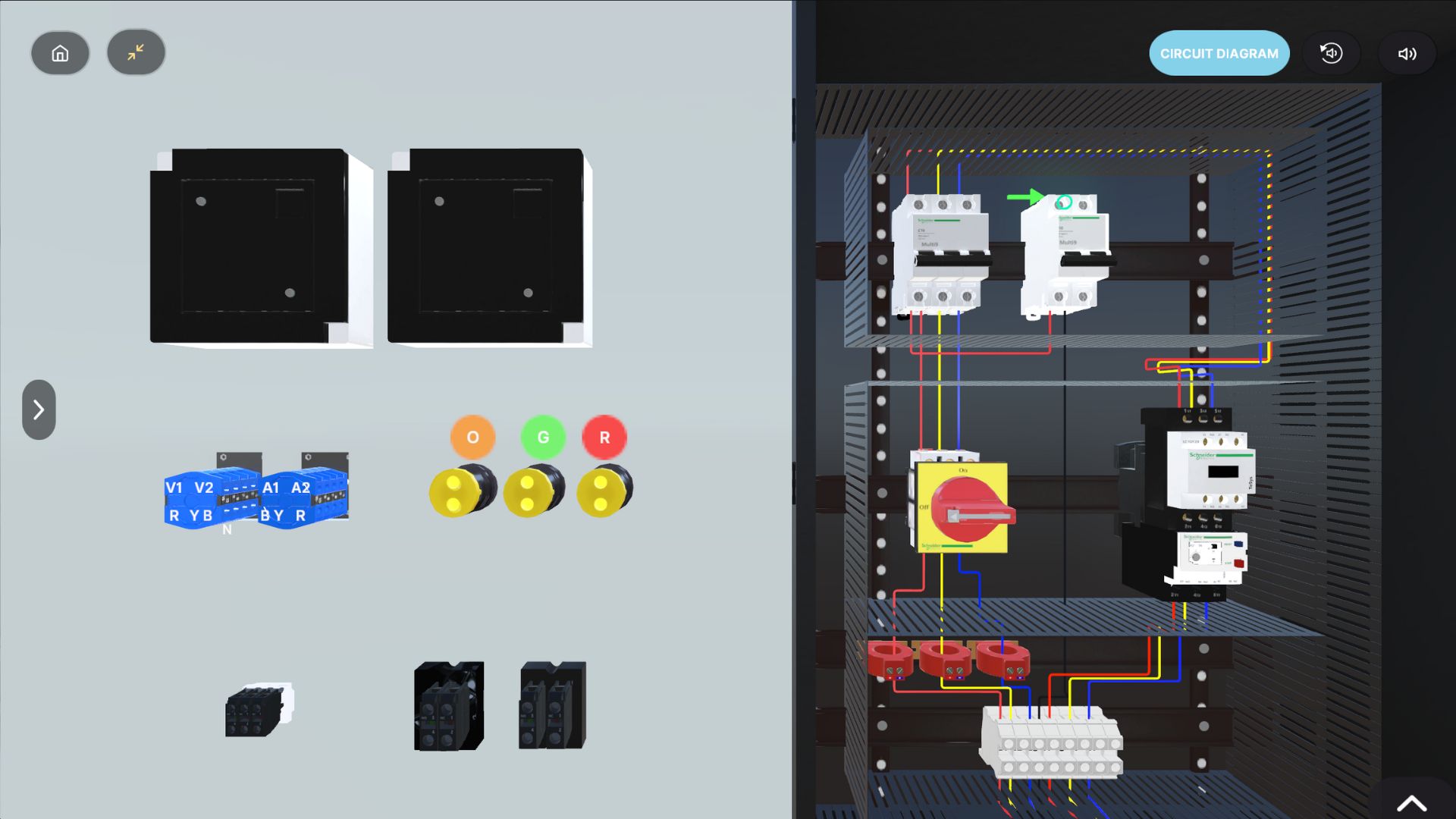

Electrical Safety for Warehouses

Isolate circuits, lockout breakers, test for absence of voltage, inspect cords, manage cable routing, avoid wet areas, report defects, restore.

Spill Response and Housekeeping

Contain spills, cordon zones, use absorbents, segregate waste, reinstate clean walkways, and document corrective actions for review.

Operations Training Modules

Forklift Operations

Complete pre-use checks, maintain stability, manage load heights, protect pedestrians, follow speed limits, and park safely with forks lowered.

Reach Truck Operations

Operate in narrow aisles, control mast tilt, lift safely at height, place pallets accurately, avoid rack strikes, and reverse carefully.

Pallet Jack Operations

Inspect wheels and forks, move smoothly, control corners, manage slopes, keep loads low, and maintain pedestrian awareness in aisles.

Scissor Lift Operations

Perform pre-use inspection, verify guardrails, assess floor stability, avoid overhead hazards, use controls safely, and coordinate with spotter.

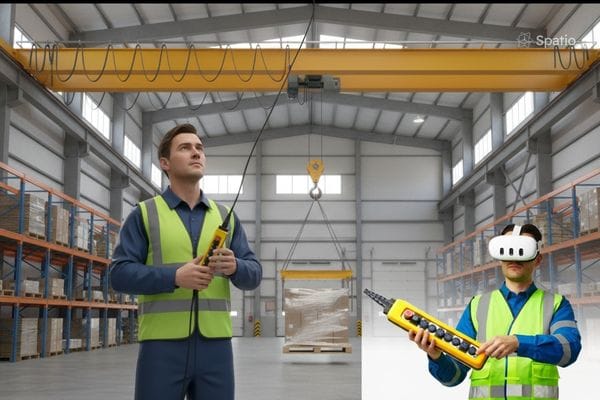

EOT Crane Operations

Operate overhead cranes, control swing, follow signals, manage blind spots, use taglines, inspect rigging, and coordinate lifts with ground teams.

Dock Leveller Operations

Verify trailer restraint, position leveller securely, confirm door clearance, manage transitions safely, and follow lockout during maintenance.

Who We Are

Spatio builds custom VR simulators for high-risk, high-throughput environments. We mirror your layouts, equipment, SOPs, and compliance needs across distribution centers and fulfillment hubs. Teams train on scenarios that match real work, improving safety, speed, and service reliability.

60%

Improvement in SOP adherence

43%

Reduction in safety incidents

75%

Increase in knowledge retention

70%

Reduction in training costs

Contact Us

Case Studies

What Our Clients Say

“VR Training cut errors and misses on our busiest lines. New hires reached safe productivity faster, and supervisors coached with evidence.”

Operations Manager

National Fulfillment Center

Frequently Asked Questions

Teams practice real tasks without risk. Repetition builds muscle memory and better decisions. Clients report fewer incidents and faster onboarding.

Yes. We replicate your layouts, equipment, scan flows, and permits so skills transfer directly to production.

Spatio supports Meta Quest, Pico, and HTC Vive. We guide headset selection, space planning, and device management for multi-site deployments.

Dashboards show completions, scores, errors, and time to competency. Session playbacks support coaching. Data integrates with your LMS and exports for audits.

Yes. Voice and on-screen text can be localized to English, Arabic, Hindi, Urdu, and other languages used across your sites.

Standard modules deploy in two to four weeks. Custom programs that mirror your equipment and SOPs typically take eight to twelve weeks.

Ready to raise safety and throughput across your warehouses?

News & Insight

We share the latest breakthroughs, innovations, andupdates in the XR & AI industry