What Is VR Safety Training and How It Works

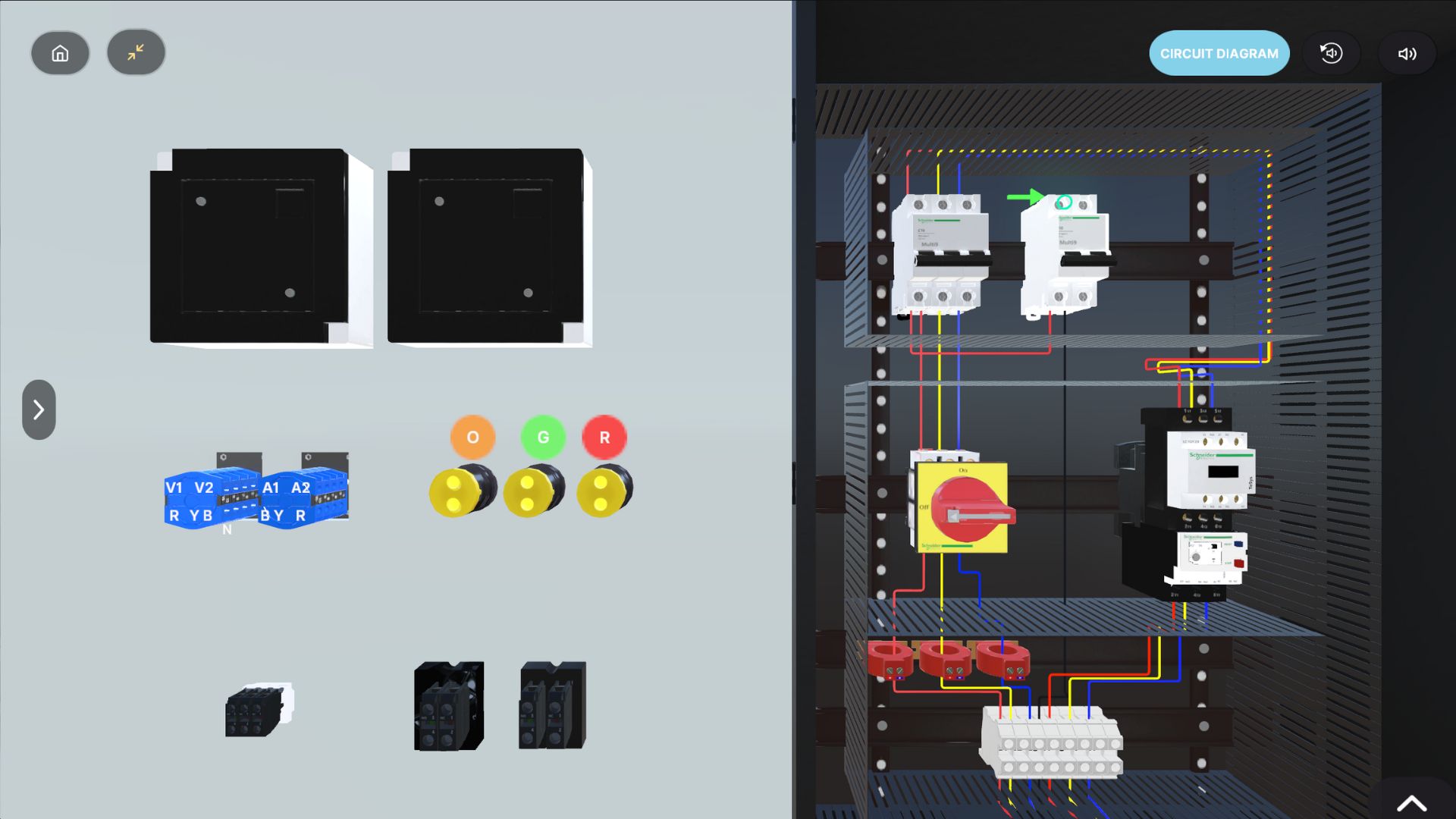

Virtual Reality (VR) training immerses users in realistic, computer-generated environments: via headsets like Oculus or Meta Quest. Trainees interact with virtual machinery, processes, and emergency scenarios, gaining experience without real-world risk. This immersive approach contrasts sharply with traditional methods like classroom instruction or on-site demonstrations.

Tangible Benefits of VR Safety Training

Higher Engagement & Retention

- VR training delivers up to 75% retention, outperforming lectures at ~5% and reading at ~10%.

- In manufacturing pilots, VR users retained ~80% of knowledge vs ~20% in manual groups .

Faster, Safer Skill Acquisition

- Training time can be up to four times faster compared to traditional methods .

- One study showed VR learners completed psychomotor tasks significantly faster and with fewer errors

Real-world Impact & Risk Reduction

- Some industries report a 70% reduction in workplace injuries post VR implementation.

- QinetiQ’s VR coal-mine safety training saw a 43% drop in lost time injuries .

Cost Efficiency at Scale

- Initial cost per user may be higher—e.g., $328 vs $230 traditionally—but after 3 years, VR costs fell to $115/person vs $230 .

- Firms report 30–70% cost savings overall and elimination of travel, facility, and equipment expenses .

Measurable Outcomes & Scalability

- VR allows precise tracking of performance metrics errors, completion times, scenarios encountered enabling continuous improvement .

- Companies like Walmart and UPS use VR for scalable safety, equipment, and soft-skills training .

Explore Our Case Studies

Limitations of Manual Training

- Low Knowledge Retention: Passive methods lead to poor long-term recall.

- Time-Consuming & Resource-Intensive: Requires trainers, physical equipment, travel, and scheduling.

- Limited Realism & Risk Preparedness: Hard to recreate emergency or hazard scenarios safely.

- Lack of Data & Standardization: Difficulty tracking progress or ensuring consistency across locations.

Summary: VR vs Manual Training Comparison

| Metric | Traditional Training | VR Safety Training |

|---|---|---|

| Knowledge Retention | ~5–20% | ~75–80% |

| Speed of Training | Baseline | Up to 4× faster |

| Incidents Reduced | Limited | Up to 70% fewer |

| Cost per Person (long-term) | ~$230 | ~$115 after 3 years |

| Scalability | Low | High (remote, repeatable) |

| Data & Feedback | Manual, inconsistent | Automated, precise |

Strategic Value for Decision-Makers

- Operational Efficiency: Faster onboarding means less downtime and improved productivity.

- Risk Mitigation: Realistic training environments prepare workers for rare but high-impact scenarios.

- Cost-Effectiveness: Long-term savings outweigh initial investment.

- Data-Driven Insights: Training metrics inform policy adjustments and safety performance.

Implementation Roadmap

- Select Pilot Scenario: Choose high-risk or error-prone tasks for VR trial.

- Define Success Metrics: Track retention, task accuracy, completion speed, incident frequency.

- Implement & Monitor: Use VR headsets and platforms; collect data for comparison.

- Analyze & Scale: Validate ROI, then expand deployment across sites.

- Iterate: Refine VR modules based on real-world training outcomes and feedback.

Virtual Reality Safety Training vs Manual Safety Training in Heavy Industry

Why Now Is the Time to Shift to VR Training

- Escalating Risk & Complexity

Heavy industries are facing more intricate processes and higher safety demands, making traditional methods increasingly inadequate. - Generational Shift

A growing workforce of tech-native employees expects engaging, immersive training—VR delivers that experience effectively. - Data-Driven ROI Expectations

Decision-makers now require measurable cost and safety improvements—VR training provides precise analytics for performance evaluation.

Key Drivers for VR Adoption in Safety Training

- Decrease in Lost-Time Injuries

Miners using VR saw a 43% drop in lost-time injuries. - Higher Engagement and Retention

VR retains up to 75% of training content, compared to ~10–30% for lectures.

Trainees report 3.75× stronger emotional response and 90% felt confident and comfortable. - Efficiency & Cost Reduction

- Task training becomes 4× faster than traditional methods

- Initial cost (~$327 per trainee) drops to ~$115 over three years due to scalability

- Airlines and heavy equipment firms save millions on materials and downtime

- Enhanced Hazard Detection & Emergency Preparedness

Construction firms using VR report a 70% reduction in injuries via hazard recognition and fall protection simulations.

Frequently Asked Questions

Studies show a 43–45% reduction in workplace injuries and lost time, across mining, construction, and manufacturing.

Onboarding/training times drop by up to 75%, and task proficiency is achieved up to 4× faster.

Yes. Though upfront costs are higher, VR becomes ~50% cheaper per trainee over time and enables substantial material and facility savings.

Absolutely 88–96% of users want more VR content, find it comfortable, and believe it enhances learning.

Initial headset discomfort, potential dizziness in 25–40% of users, and hardware investment are considerations. These can be managed with phased rollout and ergonomic guidelines .

Key Drivers for VR Adoption in Safety Training

- End-to-End Platform: Spatio supports instructional design, scenario development, deployment, and analytics across devices (headsets, desktop, mobile).

- Content Customization: We create bespoke VR modules, dangerous equipment, height safety, confined spaces, designed for your work environment.

- Detailed Progress Reporting: Track completion rates, performance metrics, errors, and retention all via intuitive dashboards.

- Scalable Solutions: Scale training across plants and shifts without adding instructors or travel.

- Ongoing Support & Iteration: We guide pilot design, support hardware rollout, fine-tune modules, and update content based on trainee feedback.

Conclusion

VR safety training is more than a technological upgrade—it’s a strategic investment yielding measurable benefits in retention, safety, and cost-efficiency. Manual methods still have niche value, but cannot match VR’s scalability, realism, or data insights. For heavy industry decision-makers focused on safety ROI, VR offers a compelling path forward.

Ready to transform your safety program?

Spatio can help you pilot VR safety training, demonstrate ROI, and scale training enterprise-wide—reducing risk, saving time, and improving compliance.

Related Posts

Nothing found.