How VR Safety Training Is Emerging in the Middle East Oil and Gas Industry in 2026

VR safety training in Middle East oil and gas is moving from “nice-to-have” to “operationally necessary” in 2026. The reason is simple. The region is scaling projects and production, and that creates constant onboarding pressure, more contractor exposure, and tighter tolerance for permit errors and unsafe decisions. Qatar’s North Field expansion, for example, is expected to start producing LNG in 2026 and expand capacity sharply, which typically means more simultaneous operations, more maintenance activity, and more people to qualify safely.

This is not a theoretical shift. Saudi Aramco has spoken for years about using VR to train operators and support realistic scenario practice that improves teamwork and understanding of complex systems. ADNOC Technical Academy has also documented using VR for Life-Saving Rules training, noting over 2,000 VR sessions since the initiative launched in December 2023, with plans to expand into process safety fundamentals.

What’s changing in 2026 and why HSE leaders care

In 2026, HSE leaders are being pushed to demonstrate competency, not just completion. Classroom sessions can explain rules, but they rarely prove whether a worker can execute the correct sequence under pressure. VR works best when it turns safety from “information delivery” into “decision rehearsal,” especially for high-risk tasks where one missed verification can escalate fast.

Another 2026 driver is consistency across a rotating workforce. Oil and gas operations in the GCC often rely on large contractor ecosystems. When the workforce changes frequently, training quality becomes uneven. VR helps standardize the experience across language groups and sites, because the same scenario can be delivered and assessed the same way every time.

Where VR is emerging fastest inside oil and gas training

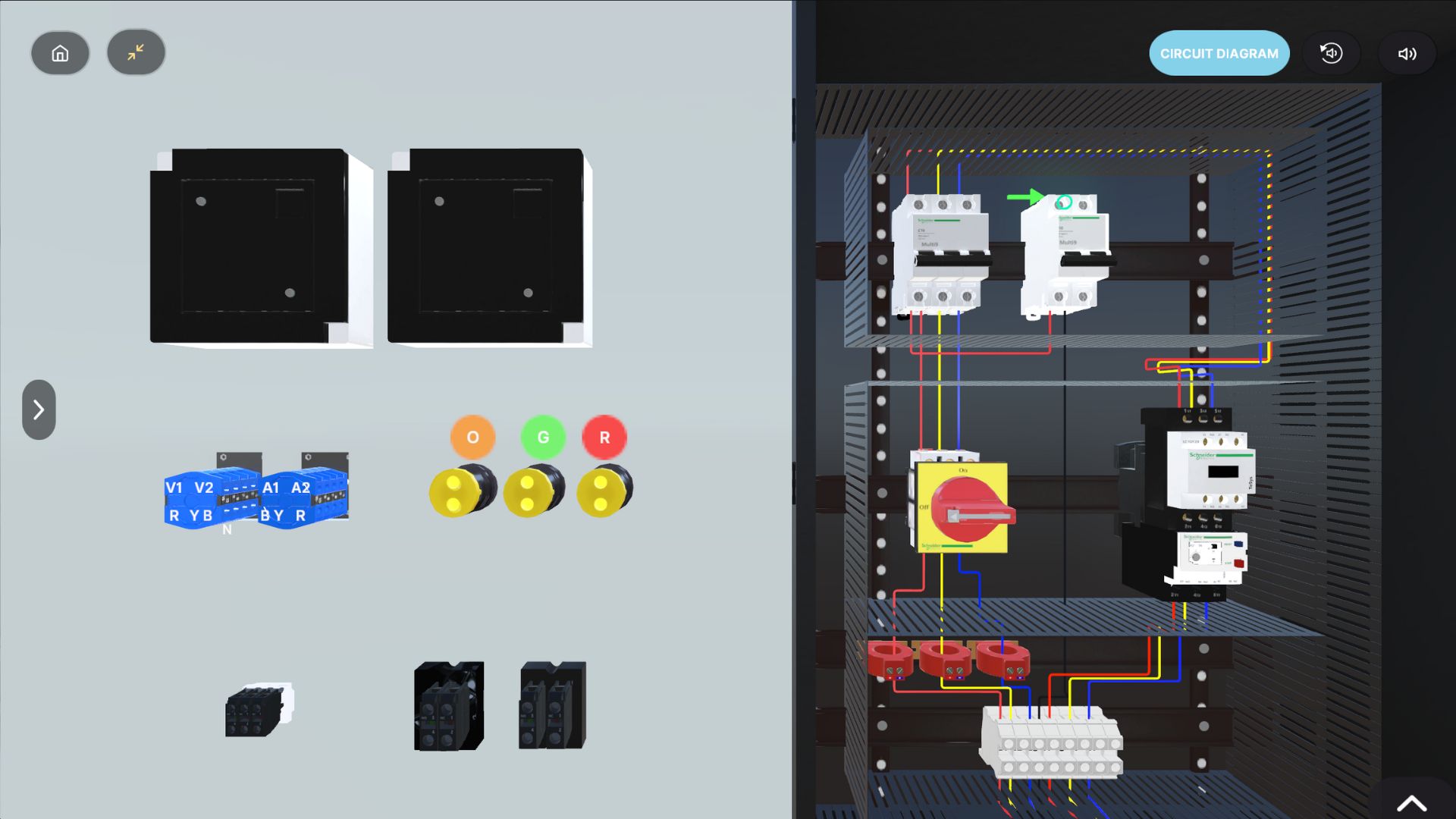

The strongest adoption is happening in scenarios that are hard to practice live without operational disruption or added risk. Emergency response is a clear example, because frequent “true-to-life” practice is difficult to run in an active facility. VR makes it possible to rehearse alarm response, route selection, muster discipline, and escalation behavior repeatedly without stopping work.

The other high-growth area is Permit-to-Work behavior, not just permit awareness. In many incidents, the permit exists, but the controls are misunderstood, verification becomes a checkbox, or roles get blurred during busy windows. VR training is increasingly being built to simulate the PTW flow as it is actually executed, including control checks and decision points, so the learner is trained on “how work is controlled,” not only “what the rule says.”

Explore Our Case Studies

What “the right VR modules” look like for 2026 Middle East sites

The best-performing VR programs in 2026 tend to focus on a small number of high-consequence workflows and make them SOP-accurate. In practice, that often means immersive training around Life-Saving Rules behaviors, confined space entry decisions, hot work readiness and fire response, isolation fundamentals, and site emergency behavior. ADNOC Technical Academy’s stated direction is helpful here, because it shows VR being used first for Life-Saving Rules, then expanding into process safety fundamentals.

The key difference between modules that drive behavior change and modules that get ignored is “decision density.” If the experience is mostly a guided tour, it will not transfer to real work. If the experience forces the learner to choose actions in sequence, under time pressure, with consequences and scoring, it starts behaving like a competency system.

How to evaluate VR safety training without wasting budget

A practical 2026 evaluation lens is to check whether a module matches your site reality and whether it can prove competence.

Site reality means your Permit-to-Work flow, your isolation logic, your gas testing expectations, and your escalation triggers. Workers immediately notice when a simulation does not reflect the real site, and that kills adoption. Competence proof means the module captures measurable outcomes, such as critical errors, missed verifications, unsafe sequencing, time-to-action, and remediation outcomes that supervisors can use to coach.

If either of those two pieces are missing, VR becomes a “cool session” rather than a safety control you can defend during audits.

Where Spatio fits into this 2026 shift

As VR adoption grows in GCC oil and gas, a lot of HSE teams are choosing partners who can build simulations around their SOPs and operational realities, rather than relying only on generic content. Spatio positions itself as a Dubai-based provider of immersive VR safety and operational training solutions, with an enterprise focus. The relevance for 2026 is straightforward. If your goal is measurable competency across sites and contractors, you need modules that can be tailored to your workflows and assessed consistently, and that is the category Spatio operates in.

What success should look like after rollout

In 2026, the most credible “VR is working” signals are operational. Faster time-to-competency for new joiners, fewer repeat Permit-to-Work errors, improved hazard recognition in the same task families, and cleaner emergency response execution during drills because people have already rehearsed the sequence. When these outcomes improve, VR stops being a training initiative and starts acting like a risk-reduction investment.

Related Posts

Nothing found.