While AI is reshaping nearly every layer of the enterprise — from logistics to customer support to procurement — one domain remains remarkably human: manual labor.

Yes, automation is advancing.

Yes, robots are learning to see, move, and react.

But we’re still years — possibly a decade — away from widespread adoption of AI-driven machines that can fully replicate the agility, judgment, and resilience of human workers in real-world environments.

Until then, every business that relies on manual processes will continue to depend on skilled human hands. And that means one thing:

Training isn’t going away. In fact, it’s becoming more critical than ever.

What AI Is Doing to Classrooms, VR Is Doing to the Shop Floor

In the last few years, we’ve seen AI disrupt the way knowledge is taught. Traditional classroom learning has evolved into dynamic, personalized, AI-powered experiences — where learning content adapts to the learner, not the other way around.

At the same time, on-the-job training — especially in manufacturing, shipping, utilities, oil & gas, and other labor-intensive sectors — is undergoing its own transformation with Virtual Reality!

VR training doesn’t replace human effort.

It enhances it, accelerates it, and de-risks it.

At Spatio, we believe VR is to manual labor what AI is to digital workflows: a tool that helps humans perform better, safer, and faster.

Why Manual Labor Still Demands Better Training

Even in the most AI-forward organizations, there are people:

- Operating cranes

- Assembling vehicle parts

- Inspecting confined spaces

- Repairing electrical systems

- Lifting, carrying, and coordinating in unpredictable environments

These roles carry risk, require judgment, and demand muscle memory — something no classroom can deliver.

This is where VR training becomes irreplaceable:

- It simulates real-world scenarios without real-world risk

- It eliminates the need for live equipment or instructor dependency

- It allows workers to fail safely and learn effectively

- It supports high-repetition, self-paced learning

And with AI and IoT layered into the experience — VR becomes not just immersive, but intelligent.

The AI-Powered LMS Behind Spatio’s Simulators

At Spatio, we’ve built our own Learning Management System (LMS) with AI-enabled performance analytics — designed specifically for enterprise VR training.

Managers can now:

- See how every trainee performs in simulation

- Identify who needs more practice — and in what areas

- Track progress across departments, shifts, and geographies

- Auto-generate reports aligned to compliance and skill benchmarks

This isn’t just data for data’s sake. It’s actionable insight for safety heads, HR teams, and operations managers — built to close the loop between training and performance.

Bridging the Haptic Gap with IoT-Enabled VR

One of the biggest challenges in virtual training has been the absence of tactile feedback — the so-called haptic gap.

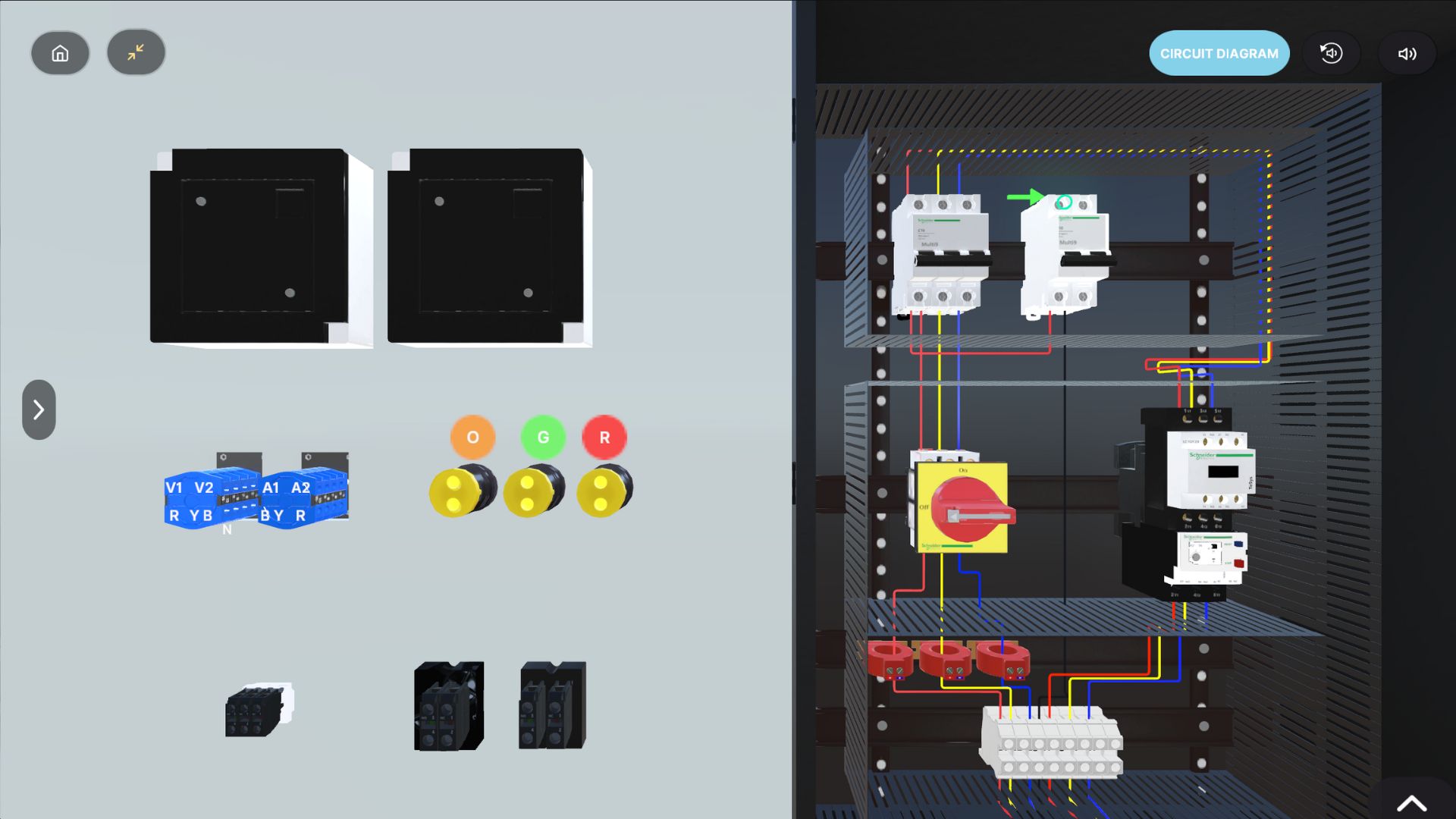

Spatio bridges this through IoT-enabled VR simulations that connect actual industrial controllers to virtual environments. Trainees now operate real joysticks, levers, and control panels — inside a virtual world.

This creates true skill transference.

Muscle memory that sticks.

Confidence that carries over.

As Long as Labor Is Human, Training Will Be Vital

AI may write code, process orders, or answer customer queries — but until machines can climb ladders, weld pipes, or safely operate heavy machinery with human-like intuition, trained human workers remain essential.

And if training is essential, VR makes that training efficient, safe, measurable, and scalable.

At Spatio, we’re not just building simulators — we’re building the systems that keep human labor safer, sharper, and future-ready.

Because the last mile of disruption isn’t about replacing humans — it’s about equipping them to thrive in a smarter world.