Shipyards at a Turning Point: Why 21st-Century Employees Need 21st-Century Training

The shipbuilding industry is standing at a generational inflection point.

Across global shipyards, a large segment of the experienced workforce is approaching retirement. Decades of tacit knowledge, judgement calls, sequencing instinct, risk anticipation are walking out of the gates.

At the same time, the incoming workforce is fundamentally different.

These are not 20th-century trainees.

These are 2K employees, 21st-century workers.

In the UAE, this shift hits harder for one structural reason: the workforce model itself is built for movement. The labour market is heavily dependent on foreign workers. In 2018, foreign workers accounted for 92.4% of the total workforce in the UAE, as reported by the ILO.

That single stat explains why shipyards and maritime operators in the UAE cannot rely only on informal, apprenticeship-style knowledge transfer. When the workforce is global and constantly rotating across projects, the industry needs training systems that can deliver skill, confidence, and consistency quickly.

The UAE maritime sector is growing, and training has to keep pace

The UAE’s maritime sector has seen sustained growth across ports, shipping, and ship repair activity. A UAE maritime yearbook notes strong performance and increased profile across key maritime segments, and highlights Abu Dhabi’s jump into the world’s leading maritime cities, reaching 22nd in the 2024 Leading Maritime Cities report, a jump of 10 places since 2022.

Growth is good. But growth exposes a constraint: capability building.

When project volume rises and timelines tighten, the question becomes simple:

Can training scale without compromising safety, quality, and throughput?

Why 21st-century employees learn differently

Shipyards are not short of ambition. They are short of time.

Your new workforce expects:

- learning by interaction, not observation alone

- feedback in the moment, not after the shift

- repetition until mastery, not one-time demos

- clarity through visuals, not only documentation

When the training environment matches how they process information, adoption and retention improve. When it doesn’t, training becomes a checkbox, and competency takes longer to show up on the floor.

What AI is doing to classroom training, VR is doing to on-the-job training

AI has changed learning departments by making training measurable, personalized, and faster to iterate.

But shipyards are not classroom environments. They are performance environments, where sequence, safety, and judgement matter.

This is where immersive and interactive training becomes the bridge:

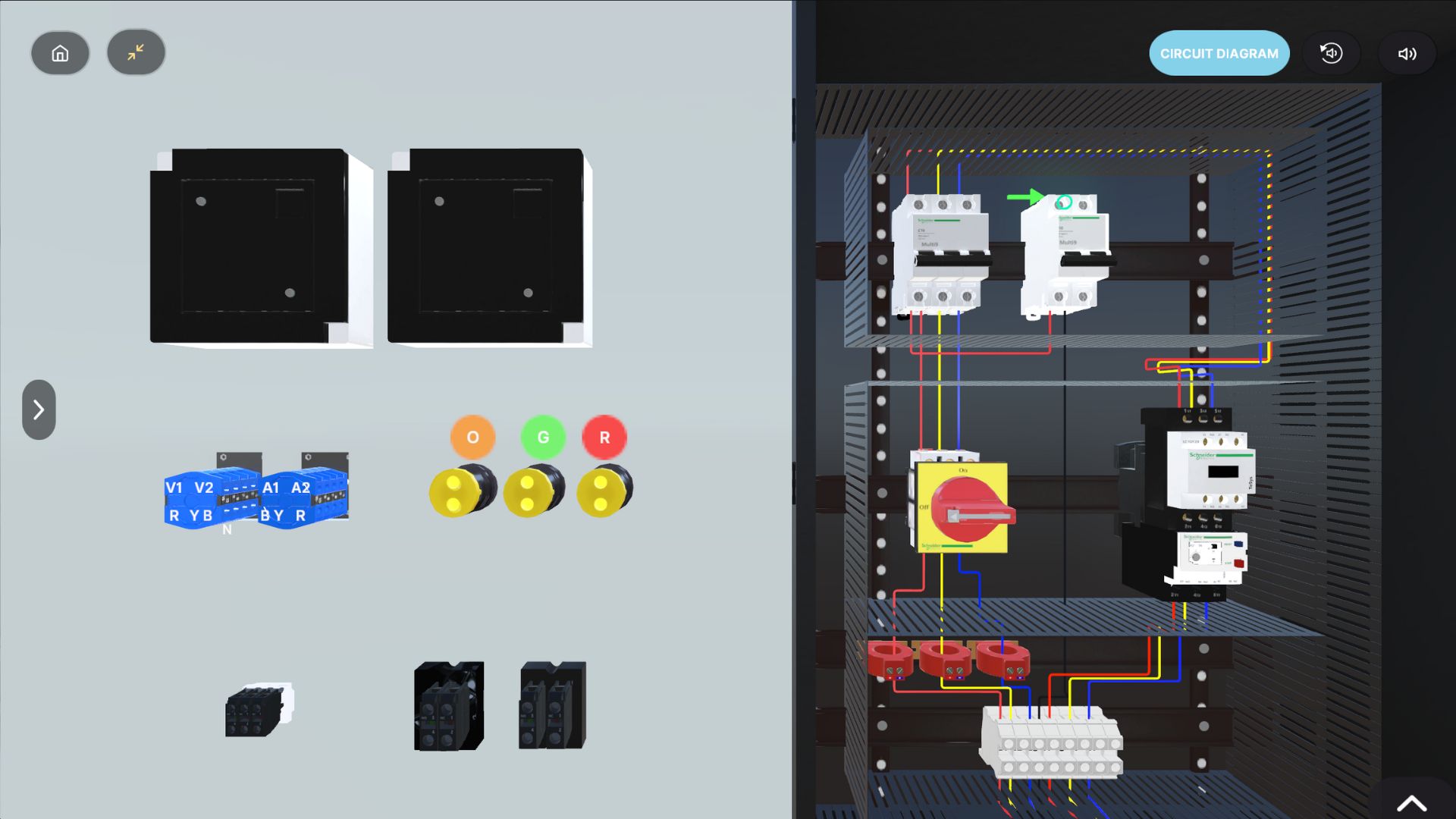

- VR makes high-risk tasks trainable without high-risk exposure

- browser-based interactive modules make training accessible at scale, across shifts and locations

- analytics makes performance visible, not assumed

Dubai’s maritime regulator itself has emphasized structured training programs to strengthen operational efficiency and competitiveness.

The direction is clear: the region is investing in capability and standardization.

Where VR and interactive learning win in shipyards

1) Risk exposure without risk

Shipyards cannot safely “teach live” for every scenario. VR enables controlled exposure to situations that are rare, dangerous, or expensive to recreate.

Examples:

- confined space failures and rescue logic

- fire escalation and response sequencing

- unsafe lifting decisions and consequence training

- near-miss pattern recognition

2) Training without live equipment dependency

Equipment availability is a training bottleneck. VR removes the dependency, allowing practice before exposure. This reduces queue time for learning and protects operations from training disruption.

3) Consistency across a diverse workforce

With a workforce made up largely of expatriates from different backgrounds and languages, consistency matters. Interactive training can standardize the “what good looks like” across sites, teams, and trainers.

4) Measurable readiness

When training is digital, performance becomes visible. Completion is not the goal. Readiness is.

At Spatio, we build VR training backed by an LMS with AI-enabled insights so managers can understand how each trainee performs, where they hesitate, and what needs reinforcement. This is how training becomes a system, not an event.

What to do next if you’re planning a modern shipyard training program

A modern training rollout does not start with technology. It starts with sequencing.

Step 1: Pick the right first modules

Start with SOPs where the cost of error is high and repetition is essential:

- confined space entry and exit

- work at height and rescue basics

- lifting and rigging decision sequences

- equipment familiarization and safe operation flows

Step 2: Design a blended pathway

Use the right medium for the right outcome:

- browser-based interactive training for rules, decision logic, hazard recognition

- VR simulation for muscle memory, sequencing, spatial awareness, pressure handling

Step 3: Make it measurable from day one

Define what “ready” means and track it:

- time to competence

- error patterns per step

- unsafe decision frequency

- retraining needs by cohort

Step 4: Build internal capability

If you want this to scale, treat it like infrastructure:

- nominate an internal training owner for immersive programs

- align IT early for deployment and device governance

- establish a quarterly roadmap for new modules and SOP updates

The bottom line

In the UAE, where the workforce is global and operational tempo is high, the old training model cannot scale cleanly.

As long as manual labour is valued, training will be valued.

And as long as training is valued, VR and interactive learning will add more value, faster, safer, and with more consistency for the next generation of shipyard talent.