LOTO VR Training, How Lockout Tagout Becomes Real Practice Across Industries

Lockout/Tagout is one of those safety procedures that sounds straightforward on paper, until you see how many things can go wrong in the real world.

A valve that was not fully isolated. Stored pressure that was not released. A second energy source that someone forgot to identify. A coworker who assumes the job is done and re-energizes the equipment.

That is exactly why LOTO VR Training works so well. It lets trainees experience the full sequence, including common failure points, without putting people, machines, or production at risk.

OSHA’s LOTO standard (29 CFR 1910.147) exists to prevent injuries from unexpected start-up or release of stored energy during servicing and maintenance. And OSHA estimates that compliance with the standard prevents 120 fatalities and 50,000 injuries each year, with injured workers losing an average of 24 workdays.

Why LOTO Training Is Hard to “Get Right” Everywhere

LOTO is not a single action. It is a chain of actions, done in the right order, with the right verification, under real-world constraints.

Across industries, the same training problems show up again and again:

- The equipment has multiple energy sources: electrical, pneumatic, hydraulic, thermal, mechanical, gravity, chemical, stored energy.

- Isolation points vary by site, machine model, and modifications over time.

- Stored energy is underestimated, especially pressure, spring tension, and suspended loads.

- Verification gets rushed, even though it is the safety hinge of the entire procedure.

- Team coordination breaks down, particularly during shift handovers, contractor work, or group lockouts.

NIOSH also flags this clearly: workers face severe injury or death during servicing and maintenance when proper lockout/tagout procedures are not followed, and recommends a hazardous energy control program with training.

What LOTO VR Training Actually Solves

VR does not replace hands-on work. What it does really well is solve the biggest gap in traditional LOTO training: safe, repeatable practice.

Practice without production downtime

Most sites cannot repeatedly “train on live equipment” without impacting operations. VR allows repetition without taking critical machines offline.

Learning through consequences, without real risk

In a classroom, mistakes are theoretical. In VR, mistakes can be simulated realistically:

- the gauge still shows pressure

- the equipment still has stored motion energy

- the restart attempt fails because isolation was incomplete

Training verification as a habit, not a reminder

LOTO performance often collapses at verification, not at shutdown. VR can enforce verification before the scenario progresses, so trainees internalize “zero energy” as non-negotiable.

Standardizing quality across sites

When companies operate multiple facilities, training drift is real. VR helps standardize baseline competency while still allowing site-specific SOP layers.

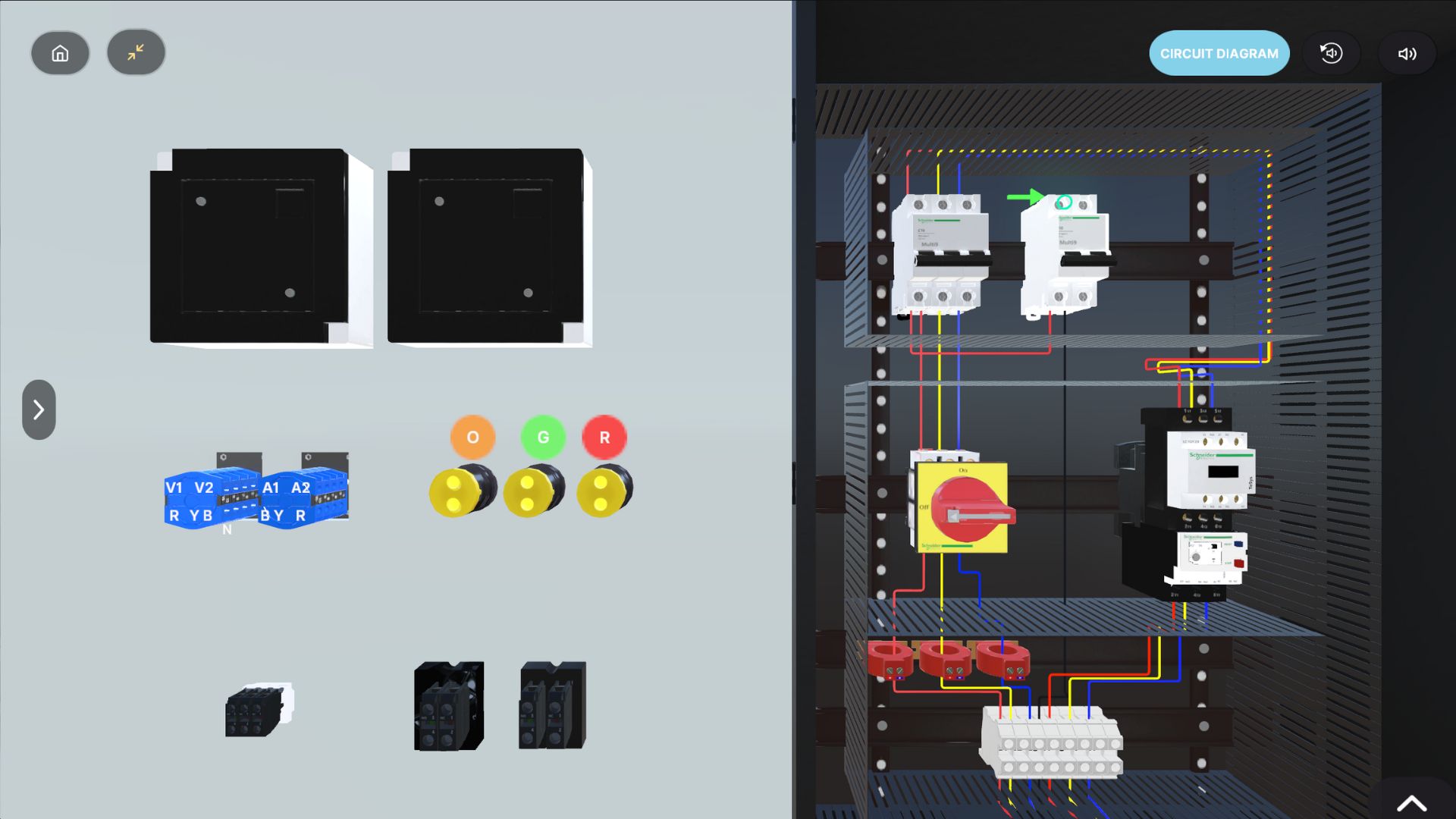

How LOTO Is Typically Modeled in VR

Good LOTO VR Training is built around the real sequence used in the field, aligned to the intent of OSHA’s standard: control hazardous energy to prevent unexpected energization, start-up, or stored energy release during servicing and maintenance.

Most VR training experiences include these stages:

1. Preparation and notification

Identify the equipment, review the work scope, notify affected employees.

2. Normal shutdown

Use correct stop sequence, avoid creating secondary hazards.

3. Isolation

Identify and isolate all energy sources, not just electrical.

4. Lock and tag application

Apply locks and tags correctly, with clear ownership and accountability.

5. Stored energy control

Bleed, vent, block, restrain, discharge, or otherwise neutralize residual energy.

6. Verification and try-out

Confirm zero energy state using indicators, gauges, and try-out actions.

7. Perform the task

Execute the maintenance, cleaning, unjamming, or inspection work.

8. Release from lockout and restart authorization

Clear the area, remove tools, confirm guards, coordinate restart, notify affected employees.

Making LOTO VR Training Work Across Industries

LOTO rules are universal, but equipment contexts change. The strongest VR programs handle this with a layered approach:

- A common LOTO backbone that teaches the universal sequence and verification discipline

- Industry-specific equipment scenarios that reflect real isolation points, hazards, and workflows

Here is what that looks like across industries.

Manufacturing

Common VR scenarios:

- conveyors and packaging lines

- presses, stamping, CNC maintenance

- mixers, rollers, material handling systems

What VR emphasizes:

- multiple isolation points

- unexpected motion and stored mechanical energy

- line restart pressure and human shortcuts

Warehousing and Logistics

Common VR scenarios:

- sorters and conveyors

- dock equipment servicing

- palletizers and automated movement systems

What VR emphasizes:

- coordination with affected workers in shared areas

- restart control when multiple teams are nearby

- visibility limitations and communication discipline

Chemical and Process Plants

Common VR scenarios:

- pump and valve isolation

- line depressurization and venting

- draining and confirming “zero pressure”

What VR emphasizes:

- non-electrical energy hazards and stored pressure

- verifying isolation via gauges and indicators

- sequence accuracy, valve logic matters

Utilities, Power, and Electrical Environments

Common VR scenarios:

- motor isolation and control circuits

- equipment start prevention and safe switching sequences

- verification discipline before intrusive work

Many organizations also align electrical safe work practices with NFPA 70E guidance, which focuses on preventing injuries from electrical hazards such as shock and arc flash.

Oil, Gas, and Energy Operations

Common VR scenarios:

- pneumatic and hydraulic isolation

- rotating equipment and compressor maintenance

- remote start hazard awareness

What VR emphasizes:

- multiple dependent systems

- stored pressure behavior

- lock ownership and coordination

Shipbuilding and Heavy Industry

Common VR scenarios:

- moving machinery, winches, hydraulic power units

- large work areas with multiple stakeholders

- group lockout conditions

What VR emphasizes:

- area clearance before restart

- group lockout logic

- preventing unexpected motion hazards

The Real “Make or Break” Elements in LOTO VR Training

Not all VR LOTO modules are equally effective. The difference usually comes down to realism where it matters, not just visuals.

1) Energy behavior must be believable

Strong VR training models real-world conditions:

- pressure that does not drop unless vented correctly

- gravity loads that remain hazardous unless restrained

- electrical indicators that reflect actual state changes

- interlocks and dependencies that can trap unsafe assumptions

2) Verification must be enforced

If trainees can “skip verification and still pass,” the training builds the wrong habit. A solid module makes verification the gate.

3) Human factors should be part of the scenario

The real world includes interruptions:

- someone asks you to hurry

- shift handover happens mid-task

- a coworker does not realize the equipment is locked out

VR can simulate these pressures safely and repeatedly.

4) Train roles, not just steps

LOTO is often a team activity:

- authorized employee applying locks

- affected employee notified

- supervisor approving restart

- contractor coordination

VR works best when it reflects how work is actually executed.

Best Practices for Rolling Out LOTO VR Training

If you want VR to improve real-world performance, not just engagement, these practices matter:

- Use VR as a readiness stage, then move trainees to supervised on-site execution.

- Start with the highest-risk, highest-frequency tasks, where mistakes are most costly.

- Include guided mode and assessment mode, so trainees learn first, then prove competence.

- Refresh modules when SOPs change, treat VR content as a living safety asset.

Where Spatio Can Help

If you are exploring LOTO VR Training, Spatio can translate your energy control procedures into interactive VR scenarios that trainees can practice repeatedly, across equipment types and industries. The focus is on realistic sequencing, verification discipline, and measurable competency, so teams build safer habits before stepping into live maintenance environments.