Controller Integrated VR Training, How Spatio Builds Real Equipment Simulators

Equipment training in VR has always had one big limitation, the haptic gap.

In a standard VR headset-only simulation, the learner sees a realistic machine, hears the environment, and follows steps, but their hands are still holding generic VR controllers. That disconnect matters in industrial training because operators do not just “know” what to do, they build muscle memory through real control layouts, resistance, switch positions, and the exact sequence of hand movements.

This is where controller integrated VR changes the game. By combining VR simulations with IoT-enabled physical controllers, we bridge the physical and virtual worlds so operators train the same way they operate, with realistic inputs, realistic feedback, and repeatable practice.

The Haptic Gap in VR Equipment Training

VR is excellent for visual learning, hazard awareness, and SOP walkthroughs. But equipment operation is different. It is tactile. Operators rely on:

- Knowing where a switch is without looking

- Building comfort with joystick travel and button placements

- Practicing coordinated two-hand actions

- Reacting quickly, based on feel and habit

When trainees use generic VR controllers for a complex machine, two things happen:

- The training becomes “screen-based learning in 3D” rather than true operational practice

- The skill transfer to the real machine slows down because the hand memory is missing

Closing this gap requires physical controls that match the real equipment and behave like it.

How IoT Bridges the Physical and Virtual Worldsy

IoT is the bridge that lets real-world physical inputs drive virtual outcomes in real time.

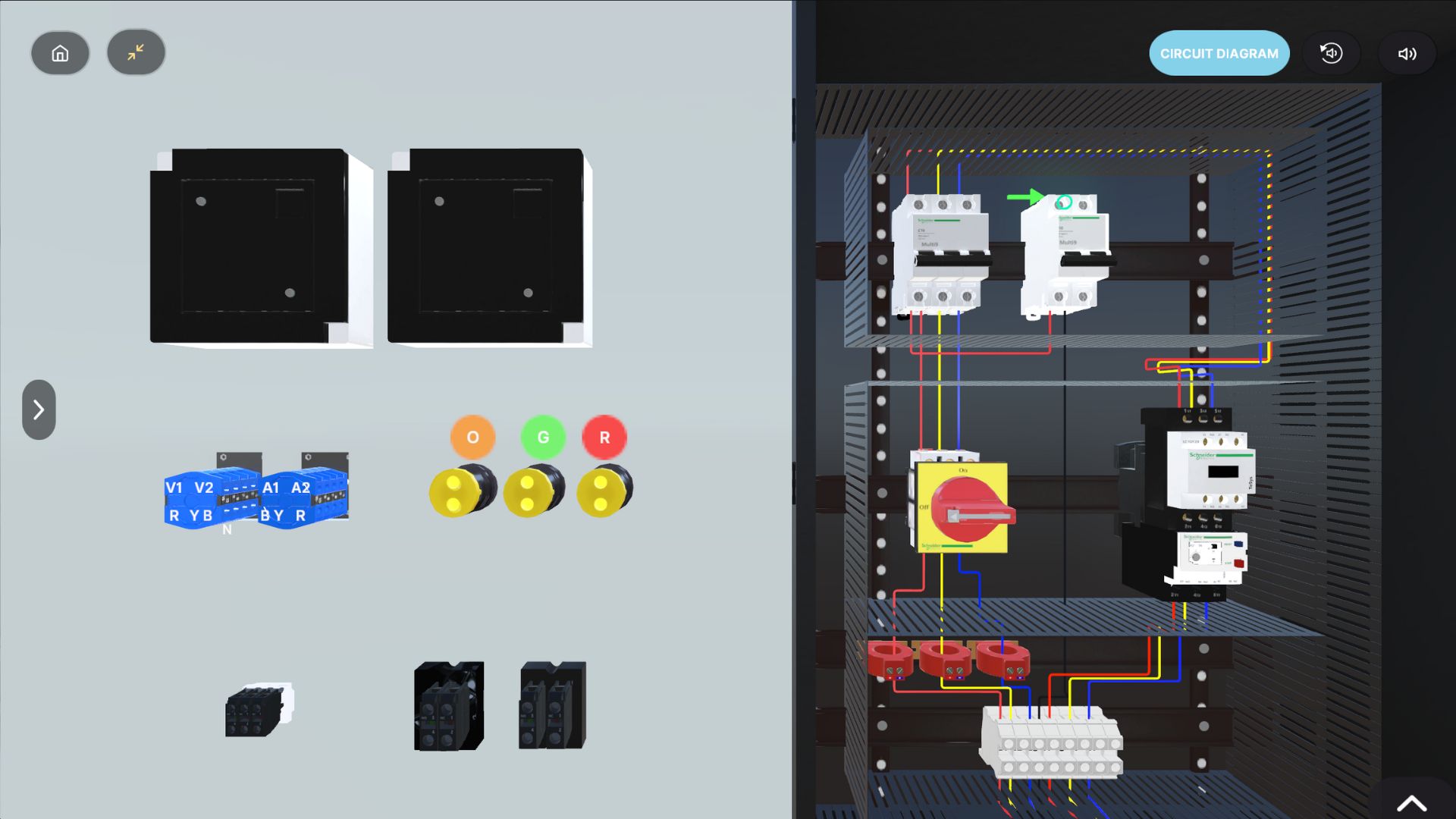

- A controller integrated VR system typically includes:

- Physical controls, like toggles, push buttons, joysticks, rotary knobs, pedals, or levers

- Sensors and electronics to capture each input accurately

- A microcontroller to process signals

- Wireless communication to send data into the VR application

- VR-side mapping to translate every input into the correct in-simulation action

The result is simple for the trainee, what they touch in the real world is what moves in VR, instantly.

This is the moment VR stops being only visual and becomes hands-on equipment training.

How Controller Integrated VR Improves Training Performance

When trainees practice with realistic controls, the training outcome changes in a measurable way. Even without changing your SOP content, the experience becomes more “operational.”

Here are the performance gains most teams notice:

Faster skill transfer to the real machine

Trainees are not learning twice, once in VR and once again on the shop floor. They build familiarity during VR itself.

Stronger muscle memory and fewer operational errors

Because controls behave like the real equipment, trainees repeat the correct actions until it becomes habit.

Higher confidence before live practice

With a workforce made up largely of expatriates from different backgrounds and languages, consistency matters. Interactive training can standardize the “what good looks like” across sites, teams, and trainers.

Less dependency on equipment availability

You can train repeatedly without taking machines out of production or waiting for the right slot.

Better assessment and feedback

Because every input is tracked digitally, you can evaluate decision-making, reaction time, and SOP adherence more objectively.

How We Build Controller Integrated VR, The Process

Below is the exact process Spatio follows to build controller integrated VR simulators.

1) Controller Design

We design and build controllers based on real machines so the form, layout, and ergonomics feel familiar to operators.

What this involves:

- Studying the real equipment interface, hand positions, spacing, and control grouping

- Designing a physical layout that matches the operator’s muscle memory

- Prototyping for comfort, grip, reach, and fatigue reduction

- Finalizing enclosure, materials, and durability for industrial use

The goal is not to build a “nice controller.” The goal is to build something an operator instantly recognizes.

2) Realistic Controls

We implement control logic and feedback so every action behaves like the real equipment, building true muscle memory.

This is where a controller stops being “buttons” and becomes “machine behavior.”

We replicate details such as:

- Toggle states and safe-position requirements

- Joystick behavior, dead zones, ramp-up, ramp-down

- Press-and-hold logic vs single tap logic

- Interlocks, sequence dependencies, and failure conditions

- Realistic timing delays where relevant, like startup checks

If a real machine requires a specific order of operations, the VR simulation enforces it. If a wrong action creates risk, VR reflects the consequence.

3) Wireless Connection

We enable smooth, wireless communication with instant response, keeping the experience immersive and cable-free.

Wireless is important because equipment training needs natural movement and posture. Cables create friction, restrict motion, and reduce realism.

What we engineer for:

- Low latency input transfer so the VR response feels immediate

- Stable connection that holds up in training rooms and industrial environments

- Battery and power design suitable for repeated sessions

- Safe reconnection handling, so training is not interrupted by minor dropouts

The trainee should not feel the technology layer. They should only feel the machine.

4) VR Mapping

We map each physical input directly into VR so the controller and simulation work in perfect sync.

This step connects the physical controller logic to the VR equipment model.

It includes:

- Defining each input, its values, states, ranges, and thresholds

- Mapping every input to a specific VR action, animation, or machine response

- Calibration so physical travel matches virtual travel

- Testing edge cases, accidental presses, and incorrect sequences

- Ensuring consistency across users, sessions, and devices

When mapping is done right, operators stop thinking about controls. They simply operate.

How Controller Integration Works Behind the Scenes

Without getting overly technical, here is the typical flow:

- A trainee moves a joystick or presses a switch on the physical controller

- Sensors detect the change, the microcontroller processes the signal

- The controller sends data wirelessly to the VR application

- The VR engine receives the input and triggers the correct equipment response

- The simulation updates instantly, visually and logically, reflecting real machine behavior

This is how we achieve physical and virtual sync, which is the core requirement for true equipment operation training.

Where Controller Integrated VR Makes the Biggest Impact

Controller integrated VR is most valuable when:

- The real equipment is high-risk or high-cost to train on

- Operators need precise control coordination

- Mistakes can lead to incidents, damage, or downtime

- Training time is limited and must be more effective

Common examples include lifting equipment, access equipment, vehicle operations, engine room tasks, and any scenario where controls and sequence discipline matter.

FAQs

No. It is especially valuable when real equipment time is expensive, or when a smaller team needs faster readiness with fewer mistakes.

Not always. The controller design depends on your training goal. For muscle memory transfer, closer is better. For SOP familiarization, partial replication can still deliver strong value.

It depends on the complexity of the equipment, number of controls, and scenario depth. The process typically includes design, prototyping, integration, mapping, and validation.

Yes. Both the simulation logic and mapping can be updated, and controllers can be enhanced if additional inputs are required.

The Future

The future of equipment training is not only immersive, it is operational.

By bridging the haptic gap with IoT-enabled controller integrated VR, Spatio helps teams train with realistic controls, realistic machine behavior, and repeatable practice that translates faster to the real world.