Off-the-Shelf vs Custom VR Training: Why One Demonstrates ROI and the Other Often Does Not

Virtual Reality training has crossed the experimentation phase. Across manufacturing, energy, logistics, and heavy industries, VR is now being evaluated not as an innovation but as an operational tool. The conversation has shifted from Can VR work? to Does this training actually deliver return on investment?

This is where many organizations find themselves at a crossroads.

Initial excitement leads to pilot programs. Budget sensitivity pushes teams toward off-the-shelf VR modules. Demos look impressive. Headsets get deployed. And yet, months later, the expected outcomes fail to materialize. Adoption plateaus. Managers struggle to justify expansion. Leadership quietly labels VR as “interesting, but not practical.”

The problem is rarely VR itself.

The problem is how VR training is chosen.

Why ROI Anxiety Shapes VR Training Decisions

VR training requires upfront investment. Hardware, software, onboarding, and internal buy-in all contribute to cost perception. As a result, many organizations approach VR with caution, treating it as a trial rather than a transformation.

Off-the-shelf VR modules appear to be the safer choice. They are faster to deploy, lower in cost, and easy to justify internally. The logic feels sound. Start small. Reduce risk. Prove value.

However, this approach often leads to a mismatch between training content and operational reality.

The Hidden Limitation of Off-the-Shelf VR Training

Off-the-shelf VR training is designed to be generic by nature. It must work across industries, geographies, and job roles. This universality is both its strength and its biggest weakness.

In real industrial environments, work does not happen in generic conditions.

Equipment layouts differ. SOPs vary. Risk profiles are site specific. Control logic changes from one plant to another. Even the sequence of tasks that operators follow is shaped by internal standards, not textbook definitions.

When employees step into a VR simulation that does not resemble their actual work environment, engagement drops. Learning feels theoretical. Managers struggle to map outcomes back to performance metrics.

As a result, ROI becomes difficult to demonstrate. Not because VR fails, but because relevance is missing.

Why Custom VR Training Consistently Performs Better

Custom VR training starts from a different premise. Instead of asking how widely content can be reused, it asks how accurately work can be represented.

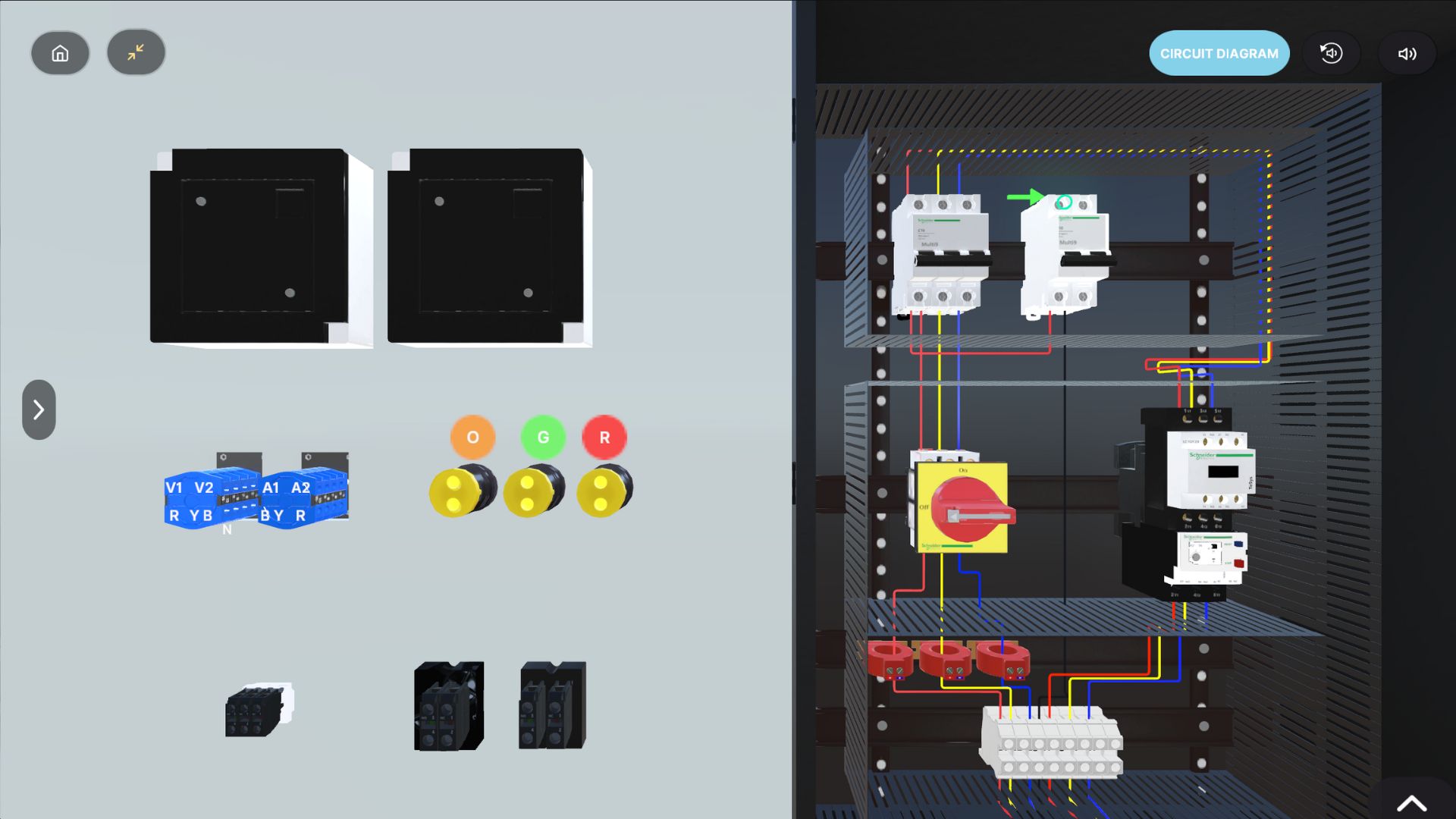

Custom modules are built around real equipment, real workflows, and real SOPs. The trainee is not learning how a task could be done, but how it is done inside their organization.

This alignment changes everything.

Operators recognize the environment. Supervisors trust the training. Mistakes made in simulation map directly to real-world consequences. Learning becomes experiential rather than illustrative.

Most importantly, outcomes become measurable. Reduced incidents. Faster onboarding. Higher procedural compliance. These are metrics leadership understands.

Key Benefits of Custom VR Training

Custom VR training delivers value across multiple dimensions:

- Operational relevance: Training reflects actual layouts, tools, and sequences used on site.

- Higher knowledge retention: Familiar environments improve cognitive recall and muscle memory.

- Improved safety outcomes: Workers practice high-risk scenarios without real-world exposure.

- Faster time to competency: New hires reach operational readiness sooner.

- Stronger internal adoption: Teams trust training that mirrors their daily work.

When training aligns with reality, ROI stops being theoretical and becomes observable.

Off-the-Shelf vs Custom VR Training: A Clear Comparison

| Aspect | Off-the-Shelf VR Training | Custom VR Training |

|---|---|---|

| Content relevance | Generic scenarios | Site and SOP specific |

| Deployment speed | Fast | Planned and phased |

| Initial cost | Lower | Higher upfront |

| Scalability | Broad but shallow | Targeted and deep |

| Operator engagement | Moderate | High |

| Safety realism | Limited | High fidelity |

| ROI measurement | Difficult | Clear and defensible |

| Long-term value | Short term exposure | Long term capability building |

When Off-the-Shelf VR Training Makes Sense

Off-the-shelf VR training is not inherently flawed. It works well when:

- Introducing VR as a concept to stakeholders

- Training on universal topics such as basic safety awareness

- Supporting non-critical or low-risk learning objectives

- Running short-term pilot programs

In these cases, speed and cost efficiency matter more than precision.

When Organizations Should Consider Custom VR Training

Custom VR training becomes essential when:

- SOP compliance is critical to safety or uptime

- Work involves high-risk environments or complex systems

- Training outcomes must be audited or reported

- Workforce scale or turnover is increasing rapidly

- VR is expected to replace or reduce field exposure

At this stage, training is no longer an experiment. It is infrastructure.

The Real Question Is Not Cost. It Is Fit.

Organizations often frame the decision as off-the-shelf versus custom based on budget alone. In reality, the more important question is whether training reflects the reality of work.

VR training delivers ROI only when it feels indistinguishable from the environment employees operate in every day.

Off-the-shelf content introduces the idea of VR.

Custom VR training builds operational capability.

The difference determines whether VR becomes a slide in a presentation or a system that quietly transforms workforce performance.