From idea to deployment, we built a fully immersive heat straightening training simulator aligned with shipyard SOPs and technician workflows.

Client

Ship Repair Industry

Type

Safety & Technical Skill Training Simulator

Platform

- VR

- Device-Agnostic

- Controller-Based Simulation

Scope of Work

- Instructional Design

- 3D Modeling

- VR Development

- Assessment Module

- Deployment

The Challenge

The client needed a scalable, standardized way to train technicians on heat straightening deformed steel structures using oxy-fuel torches – a high-risk task typically learned on live equipment. Existing methods relied on trainer-led workshops, which were inconsistent, hazardous, and difficult to repeat at scale. With workforce safety, cost, and repeatability in mind, the client sought a VR-based simulation that could accurately model heating behavior, structural deformation, and SOP-driven safety procedures – while eliminating real-world risks.

The Solution

We delivered a zero-risk, controller-enabled VR simulator that mirrors the real heat straightening process from start to finish right from PPE checks and permit verification to torch-based heating on structural members like L-angles, I-beams, T-bars, and plates.

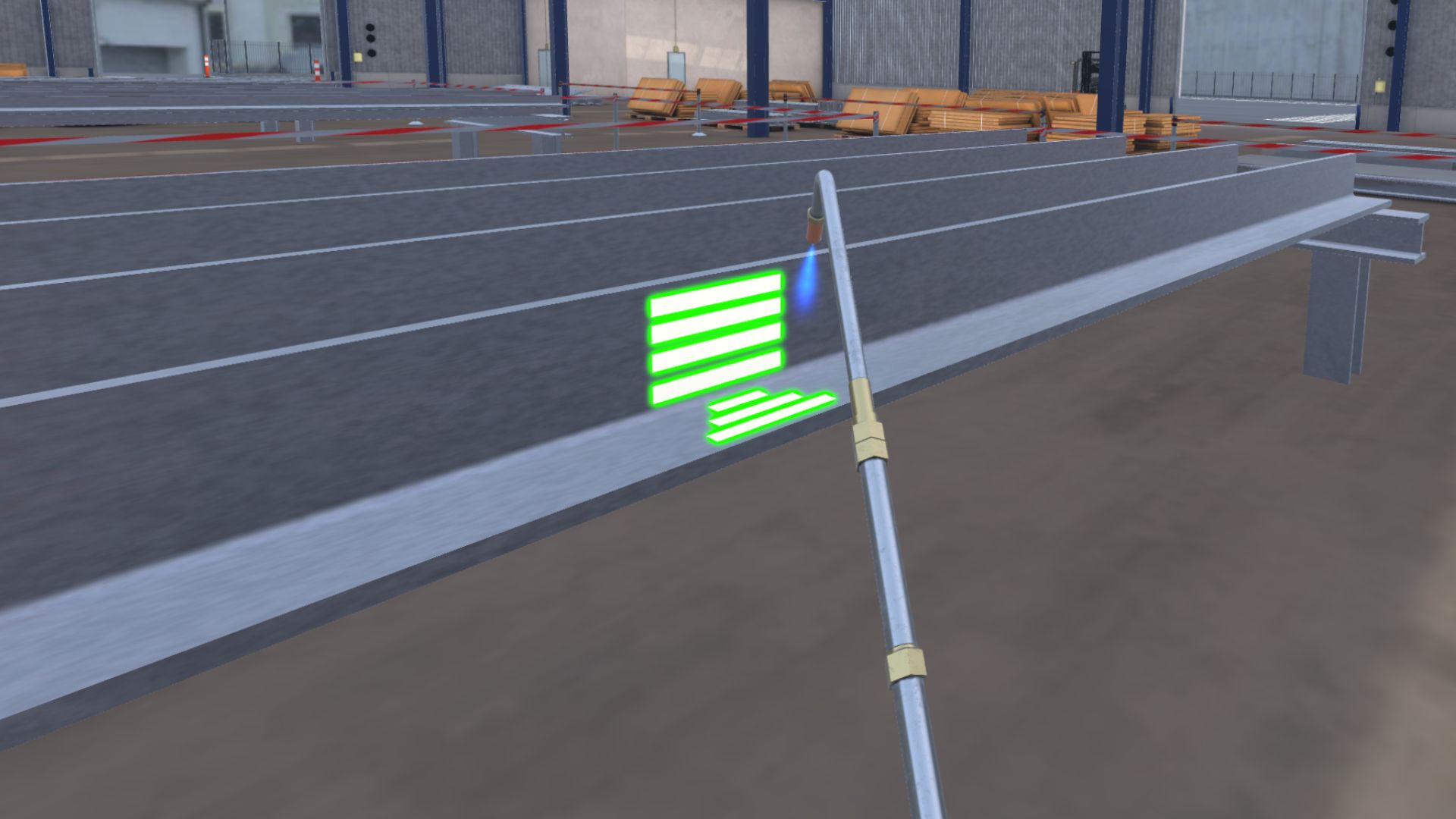

Rather than a video tutorial or app-based flow, this was built as a fully immersive VR simulation using controllers to replicate grab, mark, move, and heat actions, allowing muscle memory to form just as it would in the yard. Our focus was on capturing both procedural accuracy and thermal behavior realism, so trainees learn when, where, and how to apply heat—and equally important, when not to.

Featured Modules

Principles of Heat Straightening

Learn the concepts of thermal expansion, contraction, and plastic deformation, and how they affect steel realignment.

Identify Parameters & Torch Types

Choose flame types, nozzles, temperatures, and pressures based on material grade, thickness, and thermal constraints.

PPE & Safety Procedures

Follow correct PPE flow, safety permit verification, and barricading procedures before any heating operation.

Follow Standard Operating Procedures (SOPs)

Execute real yard protocols for equipment setup, pressure calibration, flame testing, and pre-marking of heat zones.

Apply Correct Heating Patterns

Practice line, spot, and V-heating patterns on L-angles, I-beams, T-bars, and plates as per job-specific conditions.

Final Evaluation

Complete structured tasks with scoring based on flame control, tolerance limits, sequence accuracy, and cooling cycles.

Impact Metrics

89%

increase in

SOP compliance

72%

reduction in on-the-job training time

80%

improvement in heat zone marking accuracy

0

Zero safety

incidents

Why Spatio?

Having delivered complex VR training simulators across fabrication, shipbuilding, oil & gas, and heavy industry, Spatio brings unmatched expertise in translating real-world industrial tasks into interactive, measurable learning experiences. With deep collaboration across safety heads, fabricators, and instructional designers, we engineered a heat straightening simulation that’s procedurally authentic, physically realistic, and completely safe for first-time learners.

From multi-nozzle torch modeling to thermal restraint logic, every detail is mapped from actual yard workflows. Whether you’re upskilling new hires or re-certifying experienced technicians, our VR solution offers repeatable, risk-free learning that translates directly to job performance.

Take the Next Step

See how immersive VR can reduce incidents, improve technical skill, and ensure SOP compliance across your teams.

Request a Live Demo of the Heat Straightening VR Training Simulator Today